Miniature Robot Arm

This project was first and foremost about the solution - building a robot arm and allowing the use case to develop by getting as many hands on it as possible. We were working as a group of two, and both of us wanted to build a robot arm primarily for the joy of it. Following that initial motivation, we wanted to explore use cases as of yet unexplored in current robotics and automation endeavors. Our current embodiment is controlled by four potentiometers, and I hope to go deeper by developing the code that will control the arm drawing geometrical shapes as instructed by the user.

Design Process

We started with a high level design process to allow the project the freedom to follow any number of paths, as best defined by user feedback. Starting with the robot arm, we developed minimum requirements such as being able to hold a pencil or pen, open to user interaction, and three degrees of freedom. From here we wanted the use case to be defined through experimentation.

Direction

Currently, most efforts in robotics are in the direction of replacing human labor, and it has been effective - it is estimated over 800 million jobs will be lost to automation by 2030. With such a short time horizon, there is insufficient time to retrain those workers currently at risk as well as those whose future job is unlikely to exist. The ultimate result will be a failed generation: 800 million people unemployed and unemployable. As such, we sought to develop an embodiment that accentuated human skills and activities, not eliminate the need for them.

The build

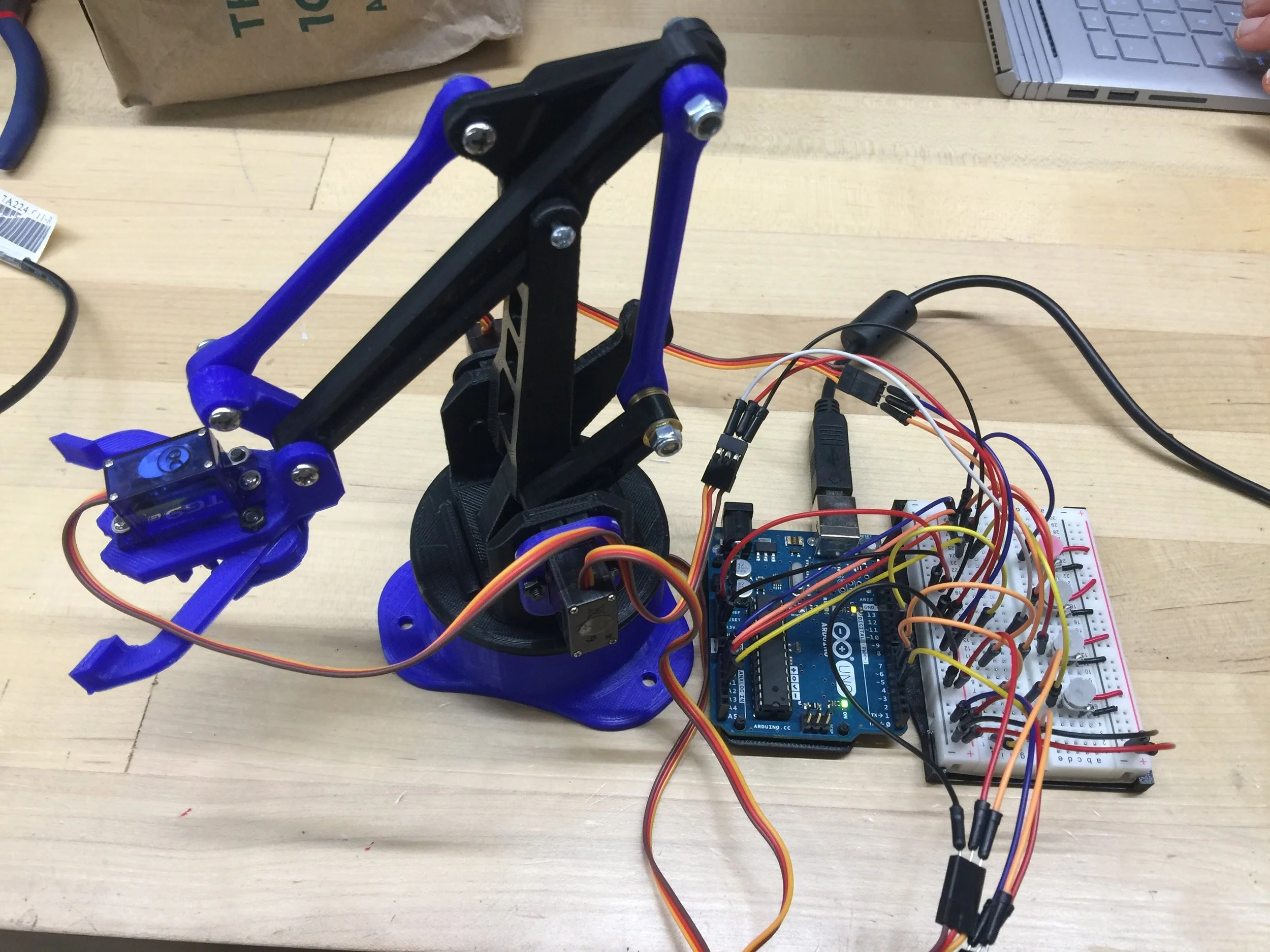

For the sake of time (this was a 2-week project in a Design Studio class), we used open source files provided on Thingiverse (Thing 1015238) for a 3D printed robot arm. My partner printed the parts and I assembled the arm, prototyped the code to get the motors working, and defined motion limits for the build.

User Testing

We put the arm in front of over 20 people to get feedback: most were design students in our class, with 5 outsiders (graduate students and friends) giving us their impressions. For this round of user testing, we used 4 potentiometers to control motion in a quasi-3D etch-a-sketch: one each for left/right rotation, up/down, forward/back, and gripper control.

Our users successfully drew arcs and picked up and moved low-weight items. However, most of them met us with a similar response: "What is it supposed to do?"

the prototype

This is a GIF of all the motors running through their test sequence. From this version was built the 4-pot model, and the next steps are to develop the code to accept user input and then produce a drawn shape, any of a circle, square, or triangle.